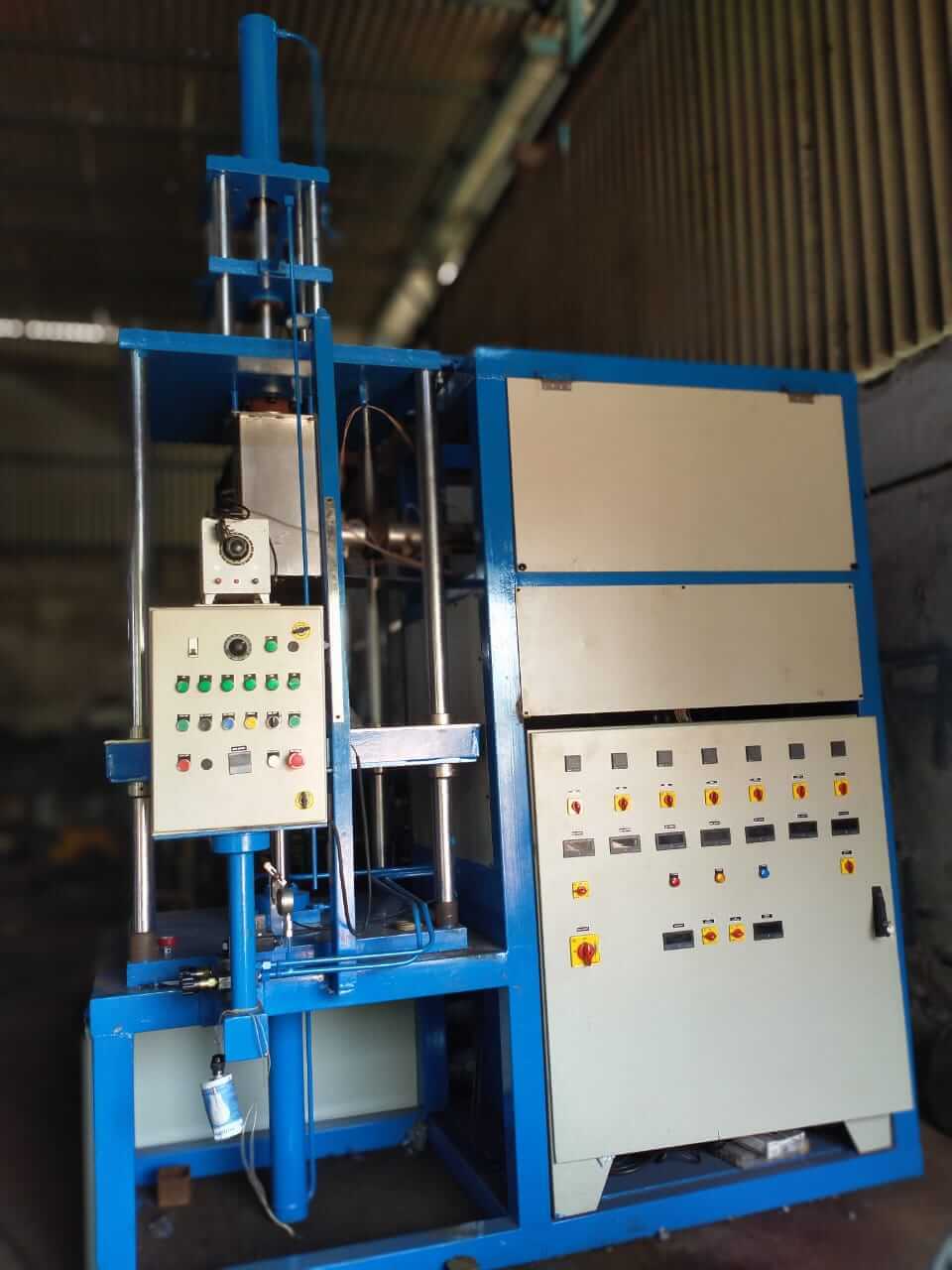

PFA Valve Lining Machine

Product Details:

- Usage PFA Valve & Pump Industry

- Body Material Steel

- Type Other

- Size 1.5 Kg - 30 Kg Stroke Capacity

- Structure Mild Steel Fabricated

- Height 3 Meter (m)

- Product Type Pfa Lined Valve

- Click to View more

PFA Valve Lining Machine Price And Quantity

- 1 Unit

- 200000 INR/Unit

PFA Valve Lining Machine Product Specifications

- 0-200 mm/s

- 2000 Kilograms (kg)

- 3 Meter (m)

- Mild Steel Fabricated

- 3 Meter (m)

- Pfa Lined Valve

- Other

- 1 Year Manufacturing Warranty

- 440 Volt (v)

- Hydraulic

- PFA Valve & Pump Industry

- 2 Meter (m)

- Steel

- Blue & White

- 1.5 Kg - 30 Kg Stroke Capacity

PFA Valve Lining Machine Trade Information

- 10 Unit Per Month

- 30 Days

- All India

Product Description

A PFA valve lining machine is a specialized piece of equipment used to line the interior of valves with perfluoroalkoxy (PFA). PFA is a high-performance fluoropolymer known for its exceptional chemical resistance, high-temperature stability, and low friction coefficient. Lining valves with PFA significantly enhances their durability and performance, making them suitable for handling harsh chemicals, aggressive fluids, and high-pressure applications.

Here's a closer look at PFA valve lining machines:

Function:

- Mold Clamping: The machine has a hydraulic clamping system that firmly secures the valve body within a mold.

- PFA Injection: Molten PFA is injected into the mold cavity surrounding the valve body at high pressure, ensuring even distribution and adhesion.

- Cooling and Solidification: The mold is cooled to allow the PFA lining to solidify and form a robust, seamless barrier around the valve interior.

- Finishing: Once solidified, the valve is removed from the mold and trimmed to remove any excess PFA.

Benefits of using PFA valve lining machines:

- Enhanced Chemical Resistance: PFA lining protects valves from corrosion and degradation caused by a wide range of chemicals, including acids, alkalis, solvents, and oxidizing agents.

- Improved High-Temperature Performance: PFA can withstand temperatures up to 260C (500F), making it ideal for use in high-temperature industrial processes.

- Reduced Friction and Wear: PFA's low friction coefficient minimizes wear and tear on the valve parts, extending their lifespan and reducing maintenance needs.

- Improved Flow Control: PFA's smooth surface promotes consistent and efficient fluid flow, optimizing valve performance.

Applications of PFA valve lining machines:

- Chemical processing industry

- Fluoropolymer Processing Industry

- PVDF Pump Industry

- Valve Industry

Types of PFA valve lining machines:

- Manual machines: These require manual operation for mold clamping, PFA injection, and cooling.

- Semi-automatic machines: These offer features like automatic mold clamping and injection, but cooling often requires manual intervention.

- Fully automatic machines: These machines handle the entire lining process automatically, from mold clamping to cooling and finishing, requiring minimal operator input.

The choice of PFA valve lining machine depends on factors like valve size, production volume, and desired level of automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+