FEP Valve Lining Machine

1000000 INR/Unit

Product Details:

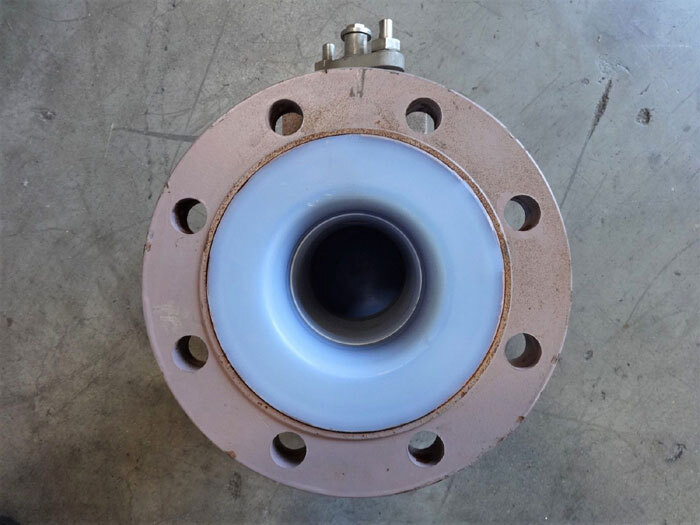

- Usage For FEP, PFA, PVDF, PP Valve Lining Process

- Body Material Steel

- Type Power Unit

- Size 1500*800*2500

- Height 2500 Millimeter (mm)

- Structure Mild Steel Fabricated

- Product Type Fep Valve Lining Machine

- Click to View more

X

FEP Valve Lining Machine Price And Quantity

- 1000000 INR/Unit

- 1 Unit

FEP Valve Lining Machine Product Specifications

- Hydraulic

- Fep Valve Lining Machine

- For FEP, PFA, PVDF, PP Valve Lining Process

- 2500 Millimeter (mm)

- 1500*800*2500

- 800 Millimeter (mm)

- 1000 Kilograms (kg)

- Power Unit

- 0-200 mm/s

- Steel

- 1 Year

- Mild Steel Fabricated

- Blue & White, Green, Yellow, Red

- 1500 Millimeter (mm)

- 220-440 Volt (v)

FEP Valve Lining Machine Trade Information

- 5 Unit Per Month

- 30 Days

- All India

Product Description

- An FEP valve lining machine plays a crucial role in enhancing the durability and performance of valves by applying a protective coating of fluorinated ethylene propylene FEP This versatile material boasts exceptional chemical resistance hightemperature stability and low friction making it ideal for protecting valves from harsh environments and aggressive fluids Benefits of using FEP Valve Lining Machines Enhanced Chemical Resistance FEP lining protects valves from corrosion and degradation caused by a wide range of chemicals including acids alkalis solvents and oxidizing agents Improved HighTemperature Performance FEP can withstand temperatures up to 260C 500F making it suitable for use in hightemperature industrial processes Reduced Friction and Wear FEPs low friction coefficient minimizes wear and tear on valve parts extending their lifespan and reducing maintenance needs Improved Flow Characteristics The smooth FEP surface promotes consistent and efficient fluid flow optimizing valve performance Applications of FEP Valve Lining Machines Chemical processing industry Handling harsh chemicals with confidence Pharmaceutical industry Ensuring product purity and sterility Food and beverage industry Maintaining hygiene and preventing contamination Oil and gas industry Withstanding harsh environments and aggressive fluids Pulp and paper industry Resisting corrosive chemicals used in processing Types of FEP Valve Lining Machines Manual machines Require manual operation for each step suitable for lowvolume or prototype applications Semiautomatic machines Offer automation for specific steps like FEP injection or cooling ideal for mediumvolume production Fully automatic machines Handle the entire lining process automatically requiring minimal operator input suited for highvolume production Choosing the Right Machine Selection depends on factors like Valve size and complexity Larger or intricate valves may require machines with higher capacity and mold flexibility Production volume Highvolume applications often benefit from automation offered by semi or fully automatic machines Desired level of control Manual machines offer customization while automatic machines prioritize speed and consistency Beyond the Coating FEP valve lining machines contribute significantly to various industries by Extending valve lifespan Reducing costly replacements and downtime Enhancing process efficiency Ensuring smooth and reliable valve operation Improving product quality Protecting products from contamination or degradation The Future of FEP Valve Lining This technology is evolving with Advanced FEP formulations Exploring options with improved properties for even wider applications Sustainable practices Development of ecofriendly methods for FEP application and waste reduction Automation advancements Further improvement in efficiency and consistency through automation So next time you encounter a valve performing flawlessly in a demanding environment remember the silent hero behind its success the FEP valve lining machine a testament to engineering innovation and a key contributor to industrial efficiency and product quality

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Press Machine' category

Back to top